Audi A3 (8V) – Reprogram new battery (Coding)

Purpose: Allows you to reprogram / recode the new battery of all its data after a replacement.

Attention !! There are, here, 5 lines of coding to do.

Proceed:

1 – Engine off, ignition off, connect your official VAG-COM VCDS cable to the computer then connect the other end to the diagnostic socket of your vehicle.

2 – Switch on the ignition then launch the VCDS program.

Line 1:

3 – Click on ” Select ” then click on ” 19 – CAN Gateway “.

4 – Click on ” Adaptation – 10 “.

5 – On this page, at the very top, there is a drop-down menu.

In this drop-down menu, choose ” Battery adaptation – Nominal battery capacity ”

6 – On this same page, there is a second drop-down menu but towards the bottom

of the page.

On the latter, choose a nominal value indicated on your battery Ex: ” 70Ah ”

Line 2:

3 – Click on ” Select ” then click on ” 19 – CAN Gateway “.

4 – Click on ” Adaptation – 10 “.

5 – On this page, at the very top, there is a drop-down menu.

In this drop-down menu, choose ” Battery adaptation-Battery technology ”

6 – On this same page, there is a second drop-down menu but towards the bottom

of the page.

On the latter, choose a corresponding value

Ex: In the case of the VARTA E39 choose ” Fabric ”

Line 3:

3 – Click on ” Select ” then click on ” 19 – CAN Gateway “.

4 – Click on ” Adaptation – 10 “.

5 – On this page, at the very top, there is a drop-down menu.

In this drop-down menu, choose “ Battery-Battery Manufacturer Adaptation ”

6 – On this same page, there is a second drop-down menu but towards the bottom

of the page.

On the latter, choose the corresponding brand:

Ex: In the case of the VARTA E39 choose “ VAO ”

Line 4:

3 – Click on “ Select ” then click on “ 19 – CAN Gateway ”.

4 – Click on “ Adaptation – 10 ”.

5– On this page, at the very top, there is a drop-down menu.

In this drop-down menu, choose “ Battery adaptation-Battery serial number ”

6 – On this same page, there is a second drop-down menu but towards the bottom

of the page.

On the latter, enter the corresponding serial number:

Be careful, only insert the last 10 digits of the serial number

Line 5 (option):

3 – Click on “ Select ” then click on “ 19 – CAN Gateway ”.

4 – Click on “ Coding – 07 ” then click “ Long Coding Wizard ” .

5 – Select byte “ 3 ” then Byte “ 3 ”.

6 – And finally change the value of bit 4-7 to the value “ 30-Battery Architecture/Type: Absorbent Glass Matt (AGM) ” then validate.

Battery status detection functions:

The battery status detection in the battery data module calculates the following variables, which are transmitted via the LIN bus to the data bus diagnostic interface J533:

1 “Battery not present” detection: If the battery data module does not detect a battery for

more than 30s, a corresponding bit is set to a

2 voltage that temporarily allows optimum charging of the battery

3 “Engine startability” bit. This indicates whether the battery is currently able to start

the engine or not

4 charge that can still be drawn from the battery before the

engine startability limit is reached

5 current battery charge status

6 battery ageing. The ageing of the battery can be determined via variables such as

the energy storage capacity and the current battery power.

7 battery open-circuit voltage

8 internal resistance of the battery

The battery sensor in the battery monitoring computer J367:

Knowing whether the battery has sufficient electrical energy to restart the engine is essential information for the operation of the start-stop device.

The control unit is located directly on the “negative” terminal of the ground cable and is connected to the diagnostic interface via the LIN data bus.

Signal usage:

The battery sensor records the following values:

– Battery temperature

– Battery voltage

– Charging current

The battery temperature is obtained using a map and the ambient temperature.

It also allows deductions to be made about the battery charging time.

Using the data thus obtained, it is possible to adapt the charging control, in particular the charging voltage, to the charging and operating state of the battery. The aim is to increase the availability of the start-stop standby device by optimally using the data from the starter battery

Consequence in the event of a fault

If the battery sensor is defective, the battery status can no longer be detected correctly.

A fault is stored in the fault memory of the data bus diagnostic interface. The start-stop device is disconnected.

Battery

The vehicle battery is housed in the engine compartment and protected by a battery tray. The size and design of the battery depend on the engine version, equipment and country variant. Standard batteries, EFB batteries and AGM batteries are used.

Vehicles with petrol engines and start/stop systems are equipped with an EFB battery, vehicles with diesel engines and start/stop systems with an AGM battery. Vehicles with auxiliary heating usually have an AGM battery.

EFB

An EFB battery (English abbreviation for: Enhanced Flooded Battery) is a reinforced wet battery. The positive plate inside the battery is coated with an additional polyester canvas. The active mass of the battery thus has an additional support on the plate. The resistance to alternating cycles of these batteries is higher than that of standard batteries. When charging, the EFB battery is treated like a standard battery.

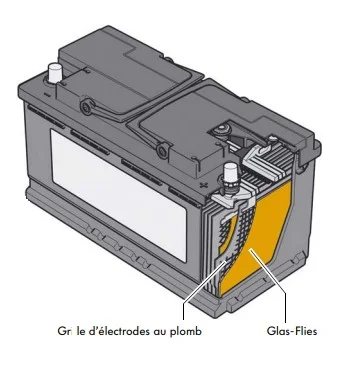

AGM battery

In AGM batteries (abbreviation for: Absorbent Glass Mat), the battery electrolyte is retained in a microporous glass mat. An AGM battery is not only characterised by an even greater resistance to alternating cycles compared to the EFB battery, but also by its leak-tightness. When charging, follow the instructions for use of the charger and select the AGM battery programme if necessary.

In the case of AGM batteries, the electrolyte of the automotive battery is retained in a microporous glass mat. In addition to

increased resistance to alternating cycles, an AGM battery is characterized by its good sealing. Sealing is of

crucial importance, especially when the battery is installed in the passenger compartment. When charging, follow the instructions for use of the charger and select the program for AGM batteries

if necessary .

Below we see the brand, serial number and manufacturer of the battery